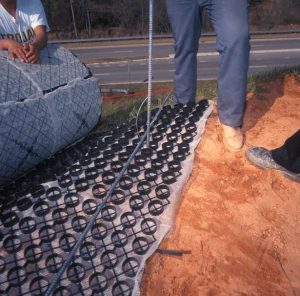

Slopetame3

Anchoring / Pinning System

The Duckbill anchor works very much like a toggle bolt. The anchor body is driven into the soil with a re-useable drive steel (drive rod) or galvanized steel rebar. Once the anchor body is placed to the proper depth the drive steel is removed. A backward pull on the cable then rotates the anchor body in the ground until it is perpendicular to the cable. This is called anchor-locking the anchor. Because the Duckbill is driven into the earth, it is actually compacting the soil around it, not disturbing it.

Step One: Insert 3 ft (1 m) long – 3/4″ (2 cm) dia. rebar into the anchor body

Step Two: Drive the anchor until the cable loop is approximately 3 inches (7 cm) below the Slopetame3 bottom (fabric/grid) and the top of existing grade.

Step Three: Fill hole made by anchor with soil.

Step Four: Pull Back on the anchor cable using a hand hook or mechanical/hydraulic Jack. The anchor cable loop should allow be brought back 3 inches – the length of the “bill.”

Step Five: Insert the rebar through the loop in the anchor cable and between the Slopetame3 rings.

Duckbill® Brochure

Model 68 Duckbill®’s are supplied with Slopetame2 at 1 per 10 m2 (108 sq ft)

Slopetame3 is anchored down with the Duckbill anchoring system.